A range of box sizes are available for Elmdene power supplies. Use the table below to identify the box size for your application.

| Box Reference |

Dimensions (mm) | PSU Range and Maximum Battery Capacity | ||||||

| H | W | D | Lid Type | 12V | Max Battery Size | 24V | Max Battery Size | |

| A | 200 | 230 | 80 | Hinge | N-Range: 1A-3A BM-Range: 1A-2A GEN2/GEN3-08 |

1 x 7Ah | TR-Range (no Battery) |

N/A |

| B | 330 | 355 | 80 | Clam | N-Range: 4A-5A BM-Range: 3A-5A GEN2/GEN3-08 GEN2/GEN3-18 |

1 x 17Ah | N/A | N/A |

| B2 | 380 | 334 | 85 | Hinge | ACCESS-PSU1 POE-ULTRAPOD-B |

1 x 17Ah | N/A | N/A |

| C | 275 | 330 | 80 | Hinge | N-Range: 1A-5A BM-Range: 1A-10A GEN2/GEN3-08 GEN2/GEN3-18 G12-24 Range |

1 x 17Ah | N-Range: 1A-5A BM-Range: 1A-10A STX-Range: 1A-5A ST/ STV Range: 1A-5A G12-24 Range |

2 x 7Ah |

| D | 500 | 400 | 80 | Hinge | ACCESS-PSU2 ACCESS-PSU2-8A ACCESS-UL-PSU2 |

1 x 17Ah | N/A | N/A |

| E | 420 | 400 | 80 | Hinge | N/A | N/A | STX-Range: 2A-10A ST/ STV Range:1A-5A |

2 x 17Ah |

| F | 380 | 230 | 75 | Hinge | GEN3-08-F | 1 x 7Ah | N/A | N/A |

| G | 440 | 250 | 115 | Hinge | ACCESS-UL-PSU1 | 1 x 7Ah | N/A | N/A |

| H | 420 | 420 | 180 | Hinge | G12-24 Range: 63/84 | 1 x 38Ah | BM-Range: 5A STX-Range: 10A ST/ STV Range: 2A-5A G12-24 Range: 63/84 |

2 x 38Ah |

| J | 185 | 200 | 53 | Hinge | VRS124000 Range: 4A (no Battery) |

N/A | TRS1 Range: 1A (no Battery) |

N/A |

| K | 325 | 350 | 105 | Hinge | N/A | N/A | ST/ STV Range: 2A-5A | 2 x 17Ah (inc. 2 x 12Ah) |

| M | 182 | 182 | 90 | IP66 | N/A | N/A | VR24x0-P Range: 4A-6A | N/A |

| P | 250 | 150 | 100 | IP68 | N/A | N/A | N/A | |

| Q | 200 | 200 | 100 | IP66 | N/A | N/A | VR2480-xP Range: 8A | N/A |

| R | 410 | 390 | 86 | Clam | GEN3-34-R | 2 x 17Ah | N-Range: 1A-5A BM-Range: 1A-5A G12-24 Range: 63/84 |

2 x 17Ah |

| S | 345 | 288 | 90 | Clam | VRS1216000-16-S (16A) VRS1220000-24-S (20A) |

N/A | VR24160-8-S (16A) VR24160-16-S (16A) |

N/A |

| T | 300 | 240 | 60 | Hinge |

VRS12x000 Range: 4-8A |

N/A | STX/ST/STV Range: 1A VR2480-xT Range: 8A |

2 x 1.2Ah N/A |

| V | 515 | 478 | 146 | Hinge | MULTI-ACCESS-PSUx MULTI-ACCESS-UL-PSU6 |

1 x 17Ah | MULTI-ACCESS-PSUx | 2 x 7Ah |

Depending on the PSU range, the PSU will detect and provide visual status that a fault is present, this can include any of the following:

The BM, GEN and EN54-4 ranges provide additional Fault diagnostic LED indications, providing the installer with more detailed information.

See specific range manuals for details.

The most common causes of battery fault condition are:

If in doubt of fuse selection – please contact Elmdene Technical Support

Overload condition: Check current being drawn by load with ammeter / disconnect load and check output voltage is correct for power supply.

Note: True battery charge voltage can only be measured with the battery(ies) connected to the power supply.

| Resistors | Colour | Code | Control Panels |

|---|---|---|---|

| 4k7/2k2 | Red | RD | ADE, Bosch, Castle, Dycon, Menvier, Pyronix, Scantronic, Texecom |

| 1k/1k | Green | GN | Honeywell, Galaxy |

| 8k2/8k2 | Blue | BL | Guardall |

| 4k7/4k7 | Grey | GY | Aritech, HKC, Siemens |

| 6k8/4k7 | Purple | PU | GardTec |

| 2k2/2k2 | Yellow | YL | Europlex |

| 5k6/5k6 | Orange | OR | DSC |

| 22k/10k | Brown | BRN | Texecom Veritas |

Please get in touch with us if you need assistance with this matter. High Security Contact internal technical details are not published.

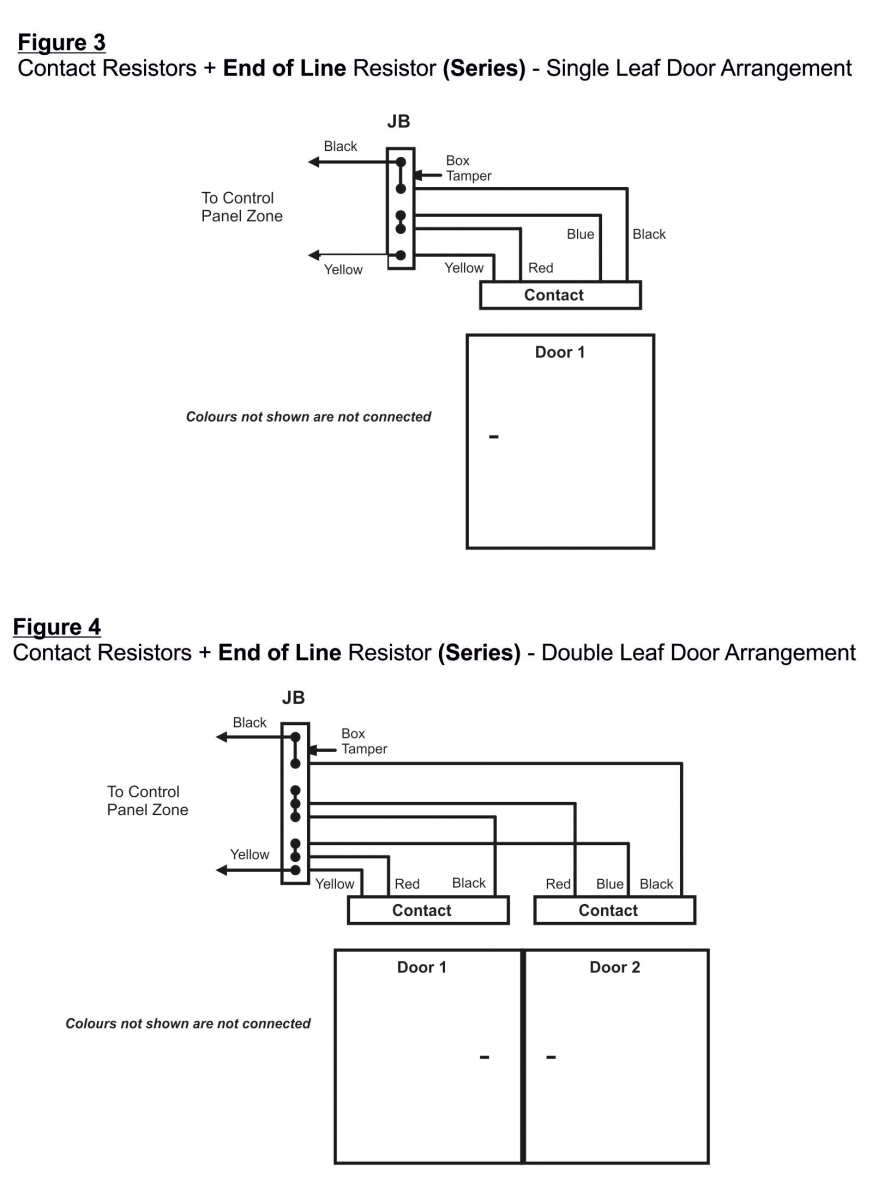

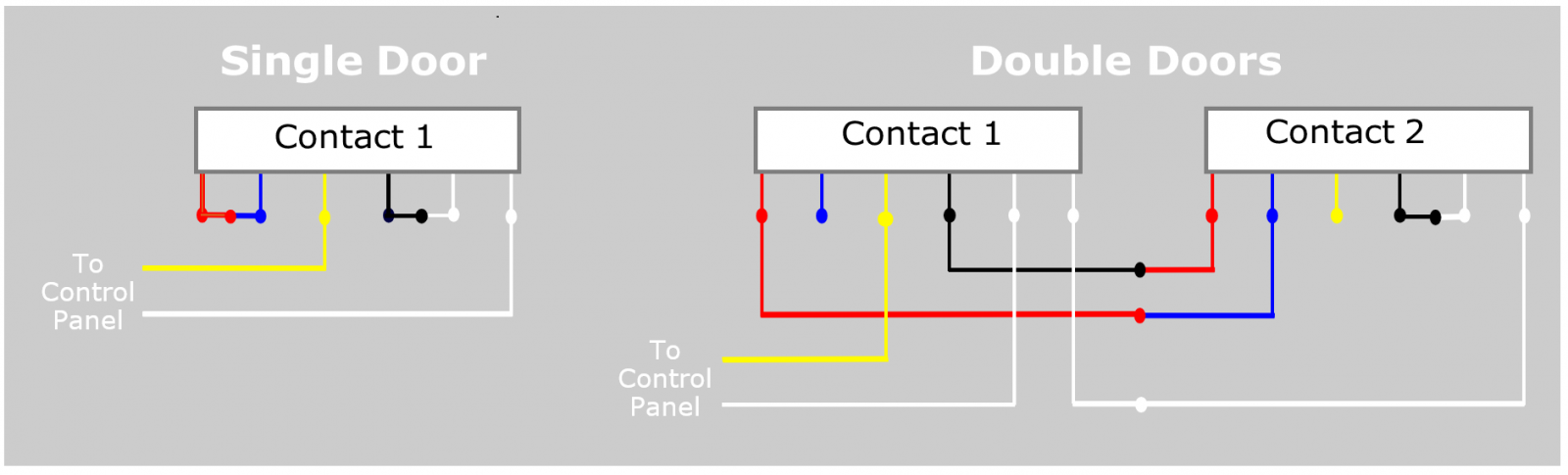

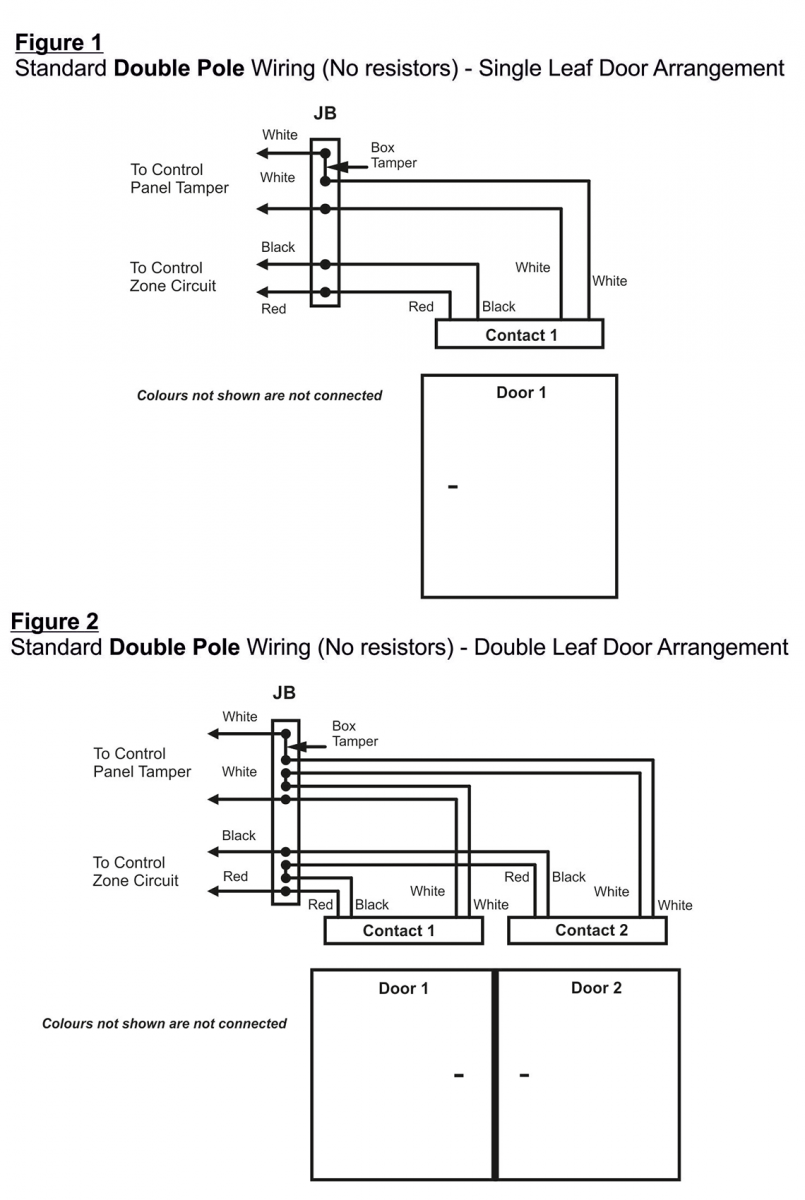

Please refer to diagrams

For all Panels except Guardall:

For 6-wire contacts, No resistors:

6 Wires contacts, with Resistors: